Services we provide

Oudisi is a leading company in China’s custom jewelry manufacturing field, providing more than just standard craftsmanship. Our diversified services improve and enhance every aspect of the jewelry production process, ensuring that each piece of jewelry stands out with impeccable quality.

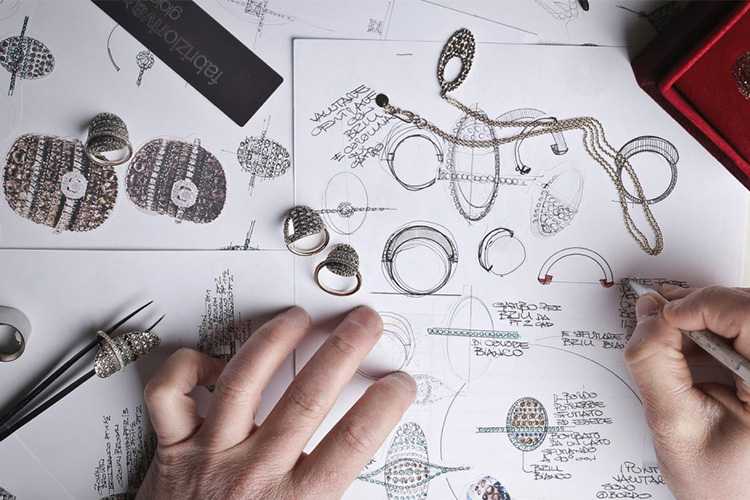

3D Jewelry Design

In today’s fast-paced wholesale jewelry market, handmade is no longer enough. Your designs require precision and a fast turnaround, and that’s exactly what Rexjewel delivers. Our team uses the latest jewelry design software to accurately and efficiently bring your designs to life.

Innovative 3D software allows us to create detailed custom jewelry and quickly make necessary adjustments before samples are made. With Rexjewel, you get modern technology combined with meticulous attention to detail, and you get the quality you seek without the wait.

Jewelry Mold Making Services

Gold Plated Sterling Silver

When it comes to jewelry mold making, our manufacturing department has the expertise to deliver exceptional quality for your designs. With over two decades of mold making experience, our skilled technicians utilize premium materials and advanced technology to capture the most intricate details of your original model. We create durable, flexible molds optimized to take your creation from concept to high-volume production.

Our custom approach means molds are precision engineered to your exact specifications. Whether for a single prototype or for repeated use in manufacturing, you can trust our mastery of mold making to efficiently transform your jewelry from idea to quality finished product. Work with us to gain specialized mold expertise based on experience serving jewelry clients around the world.

Materials used

The most common materials used for jewelry molds are silicone rubber, vulcanized rubber, and metal. Silicone molds are flexible and suitable for casting intricate details. Vulcanized rubber is more durable and suitable for casting simple shapes. Metal is used for high-volume production.

Mould making process

The process begins with an original jewelry model, usually made of wax or resin. A two-part mold is made with one half of the model embedded in each mold half. The mold halves are closed together to create a negative impression space for the casting material.

Casting Jewelry

Once the mold is made, liquid casting material (such as resin or molten metal) is poured into the mold cavity. Once it hardens, the finished cast jewelry can be removed. The mold can be reused many times to make repeated castings.

Sample Service

Explore our sample services to see the quality we can bring to your brand. Simply send us your design files and we will create samples to earn your trust. Let’s start discussing how we can collaborate to enhance your brand through our fine jewelry manufacturing.

Explore the complex world of 3D jewelry design with us. Here’s what our experienced designers can offer:

- Materials – Types of metals, pearls, gemstones, plating, etc. to complete your design

Techniques – Engraving, certain types of finishes, gemstone setting, etc.

Dimensions – Height, width, diameter, thickness of major parts and components

Features – Clasp type, fitting requirements, plating thickness, etc.

Estimated quantity – Optimize your design to your budget from the start

If you’re not sure where to start, collect images of jewelry that inspire you. Even basic 2D sketches are a solid foundation for our team

Once we receive your specifications and project concept, our team will create a visual model of your jewelry using advanced 3D design software. We’ll send you a file of this initial design for your review. Need some revisions? We’ll make adjustments until the design is exactly what you want it to be.

Jewelry manufacturing, especially when sourcing internationally, can require an adjustment process to produce pieces that your brand can trust and your customers can appreciate.

At Oudisi, we make this process easy for you. Receive custom jewelry samples within a week, allowing you to evaluate and ensure they meet your standards.

We will promptly process each modification request and continuously adjust the sample until it meets your expectations.

ODM & OEM Jewelry

We are committed to helping you succeed, so we work closely with you to guide you from the initial concept to the delivery of the finished jewelry. Our process is simplified into three key steps: discussion, design and development. At every stage, your guidance and feedback are an integral part of our approach.

consult

We begin with a comprehensive consultation covering every aspect of your project. Share your vision, including your preferences for materials, shapes, finishes and fabrication techniques.

develop

Once all the necessary details have been gathered, our skilled craftsmen will carefully produce your design using advanced CAD software. You will receive a detailed preview of the jewelry so that you can make any adjustments needed to ensure it is exactly as you envisioned.

create

Once you approve the design, we will begin production of your jewelry in the quantity and craftsmanship of your choice. Our skilled artisans will apply their meticulous craftsmanship, or we will utilize advanced CAM processes as needed. Your jewelry will be ready to sell and wear in no time.

- Negotiate design needs and specifications with jewelry brands

- Create CAD models and renderings based on desired jewelry pieces

- Develop prototypes and samples for design approval

- Precisely cut wax patterns from CAD files to create molds

- Create high-quality silicone or rubber molds for each jewelry design

- Make necessary adjustments to molds after review

- Cast jewelry from molds using selected materials such as gold and silver.

- Set diamonds, gemstones and other precious stones into jewelry

- Solder and assemble all jewelry parts

- Rigorous inspection at multiple stages of production

- Inspect metals for defects, durability, safety and purity

- Ensure all specifications and compliance standards are met

- Polish jewelry by hand or machine to achieve final shine and luster

- Apply protective coatings or plating if desired

- Pack the finished jewelry in a secure container

- Apply the desired brand, logo or other markings

- Ship the completed order to the jewelry brand

Private label jewellery

In an industry where every private label jewelry manufacturer strives to gain a competitive edge, the challenge is to meet consumer expectations while maintaining impeccable quality and staying on top of trends. For businesses, the pursuit of excellence is a top priority.

Private labeling offers a solution to provide your brand with first-class, market-ready custom jewelry at a competitive price. It’s your key to bypassing the complexities of creating and developing a product line. Discover Rexjewel’s private label services and open up a world of easy access to world-class jewelry for your business.

Need More Details?

If you need further information on any part of the process; or have an idea in mind already, feel free to let us help.