Custom Brass Jewelry Manufacturers

Take advantage of our custom manufacturing services to turn your brass jewelry dreams into reality. As a renowned OEM/ODM brass jewelry manufacturer, we transform your designs into finished products with high-quality craftsmanship. From materials to engraving and finishing, every detail is customized. Our experts produce custom brass jewelry exactly to your specifications.

Brass Jewelry Series

We offer a comprehensive range of services, from custom design solutions and private label brass jewelry collections to bulk wholesale options. Our commitment to exceptional quality, precision customization, and customer satisfaction sets us apart.

We don’t just make jewelry, we create works of art that fit your specific needs and vision. work with us, you’re not just buying jewelry, you’re entering a realm of customization that goes far beyond the jewelry itself.

Brass Jewelry Ring

Brass Jewelry bracelet

Brass Jewelry Earring

Brass Jewelry Necklace

Brass Jewelry Bangles

Brass Jewelry Pendant

Custom Brass Jewelry Manufacturers

Plating Options

Choose from small custom necklace jewelry plating kits. Choose from gold plating, silver plating, rose gold plating, and custom plating colors to perfectly match your product’s finish.

Link Chain Options

We offer custom necklace orders with different link chains. We can place your company logo pendant to make it unique to your brand.

Pearl Options

Our jewelry is available in a variety of pearl materials. Choose from pearls of different shapes to find the material that best suits your jewelry design.

Customize your brass jewelry the way you want it

With our design services and extensive customisation options, you can tailor your brass jewellery any way you like.

Custom brass jewelry

Brass jewelry combined with gold/silver offers a unique combination of affordability, durability and beauty. At Oudisi, we are passionate about providing quality jewelry that perfectly matches your market and business needs.

- High-quality brass alloy; Brass in brass jewelry is an alloy made of copper and zinc, which also contains trace elements such as nickel and lead. We ensure that the nickel content is as low as possible.

- Hypoallergenic silver/gold coating; While brass itself is not hypoallergenic, the gold and silver plating make brass jewelry safe for sensitive skin.

- >90% recycled brass/copper & 100% recyclable; We care about nature. Therefore, we ensure that more than 90% of brass is recycled and our brass products are 100% recyclable. If you share the same passion for sustainability, welcome to join the Zearrow Club.

Gold and silver on brass jewelry lasts longer

Brass is durable but easily oxidized. We use high-quality electroplating (process, thickness), which can effectively improve its overall strength.

- Silver-plated brass jewelry has a layer of rhodium added to the silver layer, making the jewelry highly water-resistant and not easy to tarnish.

- Gold-plated and gold-plated brass jewelry has a thick layer of gold to withstand daily wear and tear. The jewelry is scratch-resistant and durable.

- With the plating, the jewelry will not be at risk of oxidation and will not turn green after long-term wear.

How to Make Brass Jewelry

Step #1 Raw Material Sourcing

The first step in making brass jewelry is sourcing high-quality brass alloys, typically a mixture of copper and zinc. The composition of the alloy plays a vital role in determining the durability and color of the jewelry. Suppliers are carefully selected to ensure that quality standards are met. Sourcing the right materials sets the stage for a successful creative process.

Step #2 Design Creation

The craftsman starts the process by sketching or digitally creating an intricate design. Attention to detail is key to ensuring that each piece of jewelry meets the desired specifications. The design phase also involves client consultation to finalize custom features. Each design serves as a blueprint for subsequent manufacturing steps.

Step #3 Wax Models

Wax models of the design drawings are meticulously crafted to serve as prototypes for the final brass piece. Rexjewel prides itself on its unparalleled mold precision and quality. These molds are then inspected to ensure that they meet the design specifications. Any discrepancies are immediately corrected before proceeding.

Step #4 Casting

The brass alloy is carefully melted and then precisely poured into the wax mold. Once the metal solidifies, the wax mold is removed to reveal a rough piece of brass. The casting process is critical, as any mistakes can compromise the final product. There is no room for error in casting; this is where the skills of our artisans truly shine. The artisans ensure that each casting is a perfect match to the design blueprint.

Step #5 Polishing and Finishing

After casting, each brass piece undergoes a rigorous polishing process to remove any surface imperfections. For example, the artisan may use sandpaper of varying grits to achieve a smoother surface. Polishing and other finishing techniques can enhance the shine of the jewelry. The ultimate goal is to produce a piece that is both beautiful and durable.

Step #6 Quality Control

The final step is a comprehensive quality control inspection to ensure that each product meets industry standards. From material quality to design accuracy, every aspect is scrutinized. Substandard products are returned for rework or discarded to maintain high standards. Only products that pass these rigorous inspections are allowed to enter the market.

Perfect copper plated jewelry

Silver-plated brass jewelry

Silver-plated brass jewelry can mimic the look of sterling silver jewelry very well. The thickness of the silver layer ranges from 0.1 microns to more than 5 microns, depending on your actual needs.

Oudisi’s electroplating technology guarantees a 1-2 year color retention effect. The overall coating evenly wraps the jewelry, ensuring it is waterproof and will not tarnish.

The best choice for silver-plated brass jewelry

- Rhodium-plated jewelry protection

- Economical and durable

- Flexible thickness selection

Gold-plated brass jewelry

The standard gold plating process on brass jewelry coats the jewelry with a thin layer of gold, between 0.03 and 0.5 microns thick, which retains its color for 6 to 12 months.

The most common purity of gold plating is 14k or 18k gold. The higher the purity (18k and above), the brighter the color and the more luxurious the jewelry will look. This is why we recommend 18k gold plating over brass (copper).

Best Tips for Gold-Plated Brass Jewelry

No outer rhodium coating

Different purity of gold (14k, 18k, etc.)

Choosing micron thickness

Gold-plated brass jewelry

Gold-plated jewelry has a higher standard, with a coating thickness of more than 3 microns and a color retention period of up to 3-5 years.

For experienced brand owners and established jewelry brands, gold-plating technology is highly recommended, especially for large-scale production orders, to create exquisite luxury jewelry and enhance the brand image.

Best tips for gold-plated brass jewelry

High gold content in jewelry

Luxury choice

Recommended for small batches

Choose gold purity

Hammered Finish Jewelry

Hammered jewelry has a surface that is not perfectly flat and reflects light softly. This finish resembles the effect of ripples on water. It can be matte or high gloss.

The hammered finish is created quickly by a machine that continuously presses the surface of finished stainless steel. The machine process ensures that the pattern is exactly the same on each piece of jewelry. High efficiency and large-scale production help to significantly reduce costs.

Enamel Jewelry

Enameling refers to the lustrous finish of jewellery pieces adorned with a range of intricate patterns, dynamic designs and stunning colours. Enamel jewellery is an art form that combines the strength and durability of metals with vibrant colours.

While traditional enamelling processes involve glass powders/gemstones, the resins we use are both versatile and economical, creating colourful and affordable jewellery.

How to Tell If Jewelry Is Brass

Magnetic Testing

Brass is not inherently magnetic, a fact confirmed by Terpconnect, which notes that brass is a nonmagnetic alloy composed of zinc and copper, both of which are themselves nonmagnetic elements. This makes the magnet test an important first step in authentication. Placing a magnet near the jewelry can be a strong indication of its authenticity; if the magnet does not stick, the item is likely real brass.

Color Inspection

Brass jewelry is a distinct golden yellow in color, distinct from gold and bronze. A close look at the hue can immediately tell if a piece of jewelry is genuine. Real brass exhibits a bright, lustrous yellow hue, as opposed to darker or lighter tones found in similar metals. The uniformity of color throughout a piece of jewelry can also be a sign of brass authenticity.

Weight and Feel

The weight of real brass jewelry sets it apart from other, lighter metals. At Oudisi, the heaviness of each piece is not only a sign of its quality, but also a testament to the solidity of the materials used. When holding a piece of brass jewelry, if there is a noticeable weight that can be felt, it is usually a sign that it is genuine. The density of the metal also contributes to its long-term durability.

Acid Testing

For a more definitive identification, nitric acid can be used with caution. This acid reacts specifically with brass, often causing a color change or bubbling. While effective, this method requires careful handling and proper safety measures. It should be considered a final test after other methods have been exhausted, as it is more invasive and requires a controlled environment.

Magnetic test

Color Inspection

Weight And Feel

Embark on a journey with Oudisi

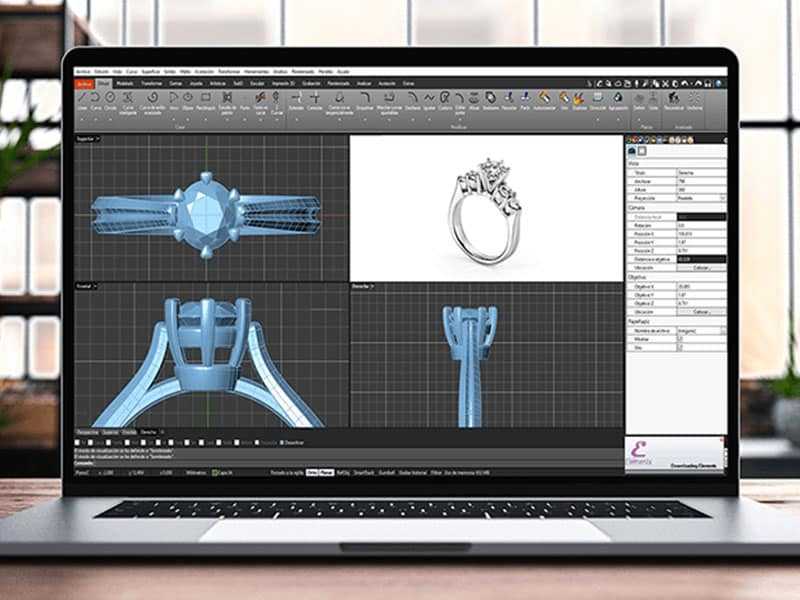

3D Rendering and Design Support

Take advantage of our carefully crafted CAD design expertise to transform your design ideas, big or small, into concrete, actionable versions.

Transparent Manufacturing

As a responsible sterling silver jewelry manufacturer, we control our own factories and every step of the production process.

Safe Return Policy

If you encounter any defective products, please don’t worry. Please contact us and our team will help you return or refund.

Need More Details?

If you need further information on any part of the process; or have an idea in mind already, feel free to let us help.